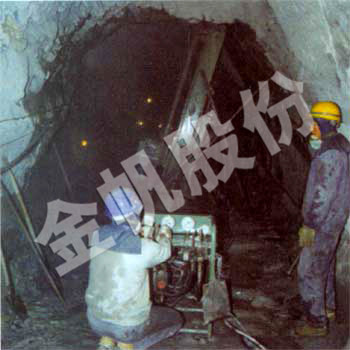

Construction of Anchor Cable Holes at Yunnan Xiaowanshui Electricity Station

Construction of Drainage Holes for Electricity Station in Longtan Water, Guangxi

| Drill depth | 80-100(m) |

| Borehole diameter | ¢130-¢220(mm) |

| Drill pipe diameter | ¢114×1500,¢89×1500(mm) |

| Drilling angle | -90~30° |

| Power head output speed (forward and reverse) | 5-180rpm |

| Rated output torque of power head | 3500NM |

| Power head stroke | 1800 mm |

| Mast sliding stroke | 500 mm |

| Powerhead with high lifting force | 45KN |

| The power head provides high thrust | 30KN |

| Rated Pressure Of Hydraulic System | 18Mpa |

| Electricity machine Model Y200L-4 power | 30KW |

| Overall Dimension | 3400×1000×1500(mm) |

| Drill weight | 1700Kg |

| Weight of major components (excluding Electrical machines) | 200Kg |